Overview

TheZKYL type self-control hydraulic tensioning device is designed based on the characteristics of China's belt conveyor by absorbing advanced technology from industrialized countries around the world, considering the different needs for tension during the start-up and normal operation of the belt conveyor and reasonable analysis and research of the conveyor belt tension model.

The characteristics of this machine are as follows:

(1) The starting tension and normal operating tension can be adjusted according to the needs of the belt conveyor tension, and the requirement of starting tension being 1.3 to 1.5 times that of normal operation can be fully achieved. Once the electro-hydraulic system is set, the tensioning device automatically operates according to the predetermined program to ensure that the conveyor belt runs in the ideal state.

(2) It has quick response. When the belt conveyor is started, it is in an unstable state. At this time, the tensioning device compensates for the elastic oscillation of the conveyor belt in a timely manner through the rapid expansion and contraction of the oil cylinder, effectively realizing the dynamic tensioning of the belt conveyor so as to reduce the impact dynamic load during the starting of the belt conveyor and make the starting smooth and reliable and also effectively avoid the over tensioning phenomenon of the tensioning device on the conveyor belt.

(3) It provides timely breakage detection signals when the belt breaks to control the automatic shutdown of the belt conveyor and provide the automatic increase of tension when the conveyor belt slips and other protection functions.

(4) It has compact structure and small installation space.

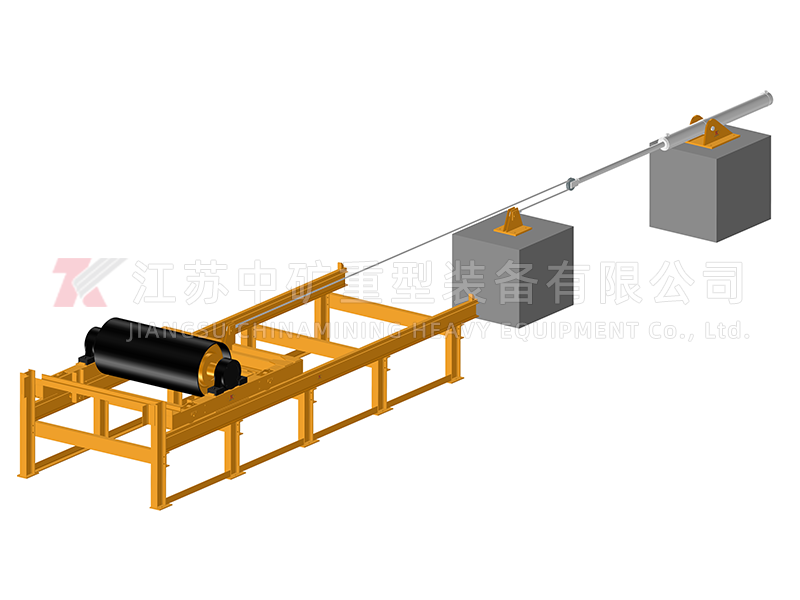

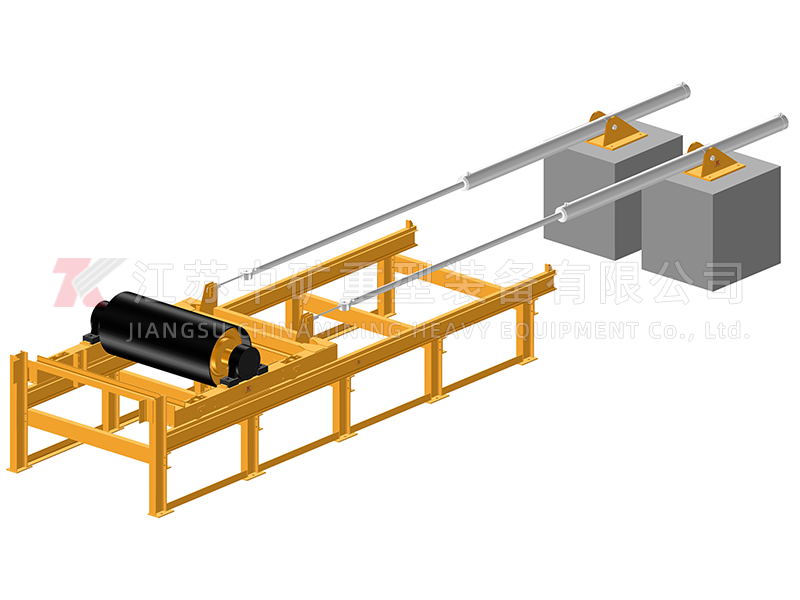

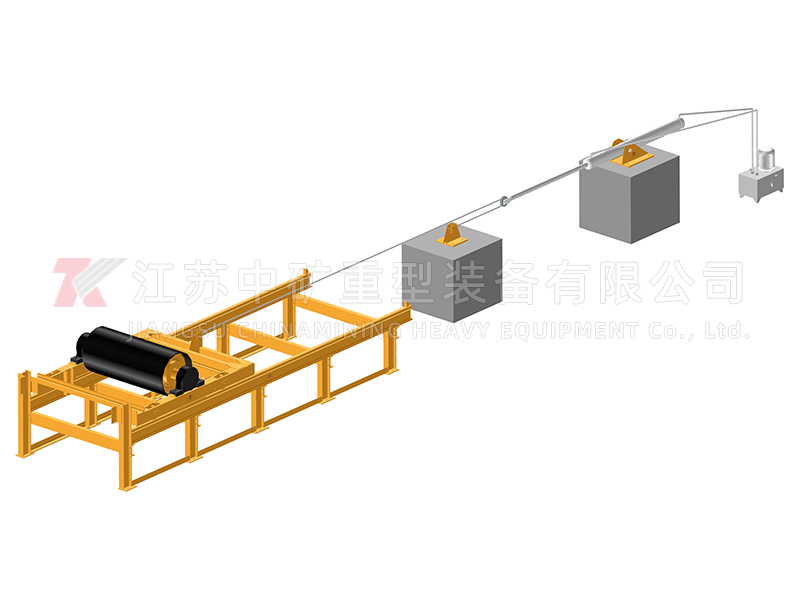

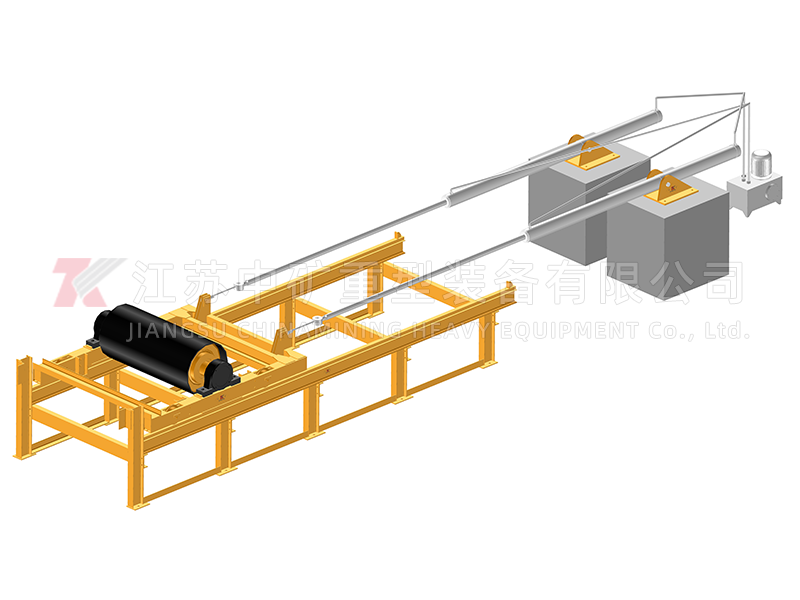

(5) It can be connected to the centralized control device to achieve remote control of the tensioning device. The general layout of this device is shown in the figure. It consists of five main parts: hydraulic pump station, tensioning cylinder, energy storage station, electric control box and accessories. The tensioning cylinder is connected to the tensioning trolley through pulleys and wire ropes. According to the different installation methods of pulleys and winding methods of wire ropes, there are seven installation methods. Users can choose according to the maximum tension, tension adjustment range and tension stroke of the tensioning trolley as well as the actual situation of the matching belt conveyor. It is required that the placement location does not drop coal, mineral powder, water and so on.

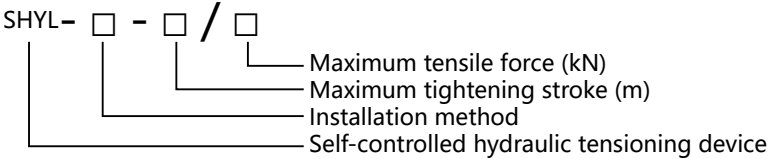

Model and parameter description:

Maximum tensile force (kN)

Maximum tightening stroke (m)

Installation method

Self-controlled hydraulic tensioning device

Example: SHYL-01-4/100 represents the first installation method, with a maximum tightening stroke of 4m

and a maximum tension of 100KN.