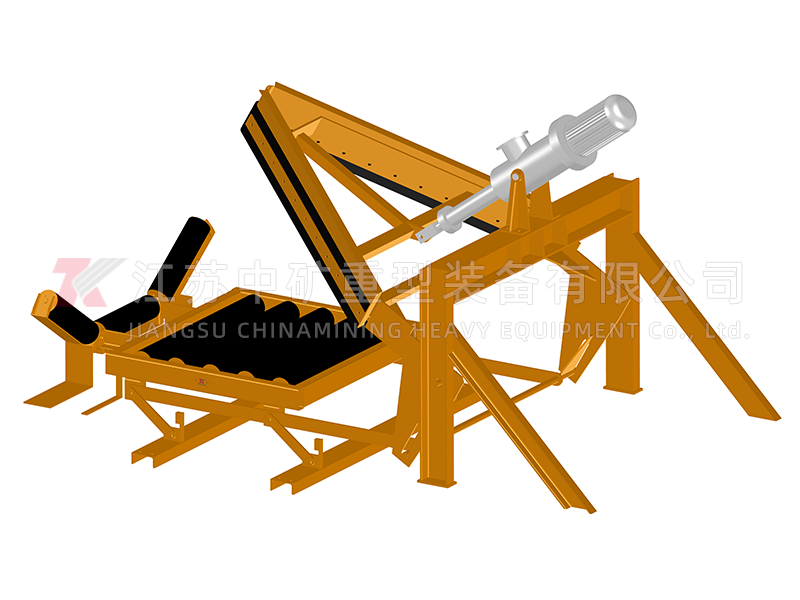

1. The scraper device of the belt conveyor is powered by an electric hydraulic push rod, which drives the lifting and lowering of the front scraper blade. When working, the push rod is extended to act on the driving rod, driving the frame forward, completing the descent of the scraper plate and supporting the flat roller group to make the working surface of the belt flat. The lower edge of the scraper plate is tightly attached to the belt surface, scraping the moisture on the running belt to both sides of the belt conveyor. When the scraping is completed, the push rod is started to retract and act on the driving rod, driving the frame to retreat, lifting the scraping plate, and making the variable groove angle roller group to return to the groove shape from flat shape, restoring the working surface of the belt to the groove shape and allowing the material to pass smoothly.

2. The electric hydraulic push rod adopts hydraulic transmission and has automatic overload protection performance. When the operation is obstructed, the pressure in the oil circuit increases to the set limit, and the overflow device quickly and accurately overflows, implementing overload protection.

3. The front scraper blade is made of polyurethane rubber plate, which can be in full contact with the belt surface, making it easier to wipe the water more cleanly.

4. Applied to the conveyance of all kinds of materials and widely used in industries such as building materials, metallurgy, chemical industry, petrochemical industry, coal industry, mining, papermaking, electricity, ports and terminals.