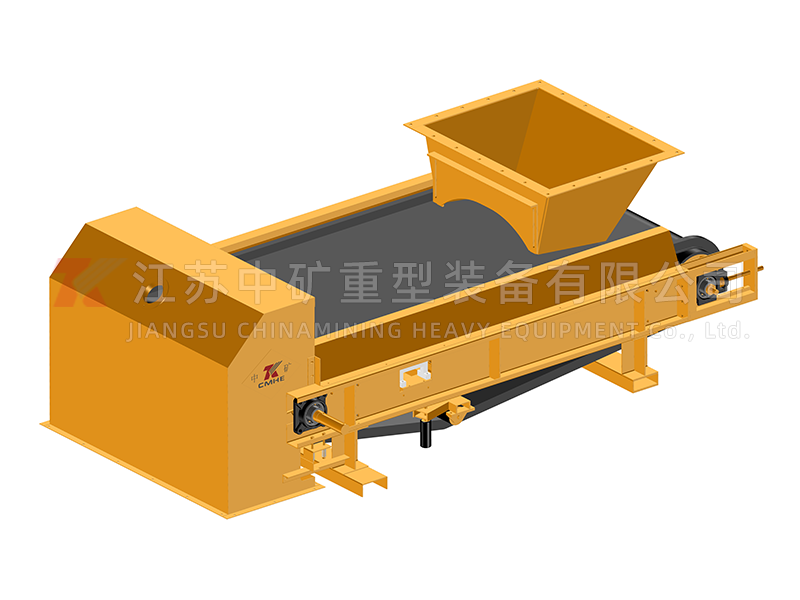

Constant feeder is ideal equipment for continuous weighing and feeding of bulk materials. It is a high-tech product that integrates conveying, weighing and quantitative control, which is technologically advanced, stable and reliable, cost-effective, durable and capable of adapting to various production environments, continuously feeds and measures various blocks and granular materials (such as limestone, iron powder, clay) and powdered materials (such as fly ash, cement), providing accurate measurement data for production control and management in various industrial sites. Equipped with RS485 upper computer communication interface, it can form a DCS system with the central control computer. Constant feeder is widely used in industries such as building materials, metallurgy, power, chemical industry, coal, coking, mining, tobacco, grain, environmental protection and ports. With a measurement accuracy of ≤ ±1%, it is an ideal choice to replace imported equipment. Feeding capacity is from 0.05m3/h to 1000 m3/h. Transport bandwidth is from 500mm to 1800mm. The center distance of the drum is from1000mm to 8000mm. Specific dimensions can be customized according to user requirements.

Principle

The load and speed signals of the conveyor belt are transmitted to the measurement and control instrument or industrial computer. The instrument or industrial computer performs internal calculations on the load and speed signals to calculate the actual feeding amount. The actual feeding amount is continuously compared with the set feeding amount to control the speed of the conveyor belt and make the feeding amount as close to or equal to the set feeding amount as possible.

Characteristics

1. A high-resolution weighing sensor with a minimum displacement of 0.1 millimeters ensures accurate measurement values.

2. High resolution digital pulse speed sensor ensures accurate speed values are obtained.

3. Gravity automatic tensioning device ensures constant belt tension, avoiding belt slippage and excessive tension.

4. The automatic belt self-aligning device prevents production from being affected by belt deviation.

5. The pear-shaped blade clears the debris on the lower belt to one side, avoiding damage to the belt caused by debris between the belt and the roller surface.

6. Blades on both the inside and outside of the belt should be used to prevent material from sticking and tare weight change.

7. No need for assistance, belt replacement is convenient and maintenance is simplified.

8. The main and auxiliary rollers are equipped with automatic self-aligning bearings, making installation and adjustment very convenient.

Main technical parameters:

The actual feeding accuracy of various bulk materials is better than the feeding rate set at ± 0.5%.

The feeding rate is approximately 50kg/h-180t/h.

Transport bandwidth is from 500mm to 1800mm.

The center distance of the roller is from 2000mm to 8000mm, using a plug-in system, and the size can be

customized according to user requirements.

Output interface: Multiple options available which can be connected to DCS system.

Environmental temperature:

Scale body -10℃ ~+60℃

Instrument -10℃ ~+45℃

Working power supply:

Instrument AC220V ± 15% 50Hz ± 2%

Scale body AC380V ± 15% 50Hz ± 2%