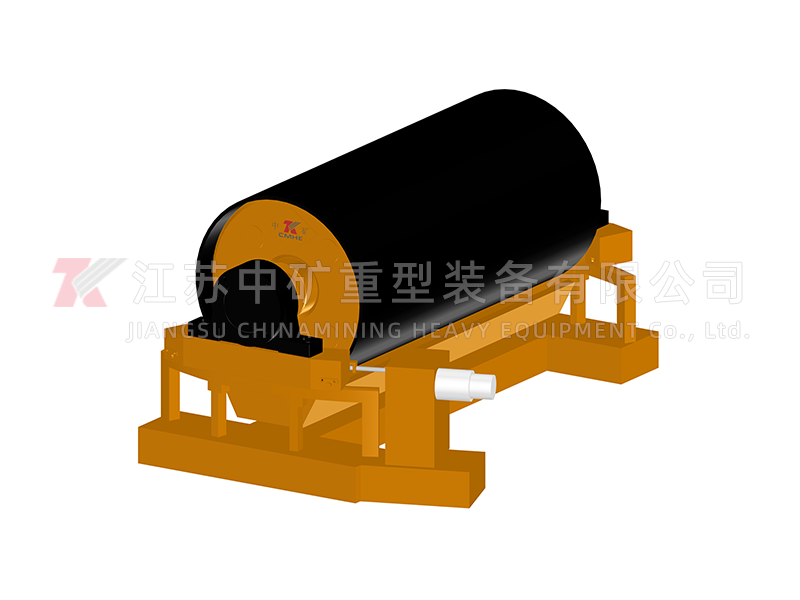

The automatic hydraulic deviation alignment equipment is equipped with two vertical inspection and driving wheels at the same height at both ends of a set of alignment rollers on the frame. The inspection and driving wheel shaft is connected to the oil pump power input shaft. Two fixed brackets are used to fix the inspection and driving wheels at the left and right ends and the oil pump on the alignment roller bracket. The tail of the composite oil cylinder is hinged to the fixed bracket. The piston rod of the composite oil cylinder is connected to the rolling part of the roller bracket of the self-aligning idler. The oil port of the oil pump is connected to the tail of the composite oil cylinder through an oil pipe. When the belt deviates to the left, it triggers the left inspection and driving wheel, and the left oil pump outputs pressure oil agilely. It enters the rodless chamber of the oil cylinder through the oil circuit integration block of the composite oil cylinder, pushes the piston and piston rod, and the hydraulic oil of the rod chamber returns to the oil tank of the oil cylinder through the oil circuit manifold block, and the piston rod extends agilely. Push the centering idler to roll clockwise (i.e. the left side of the centering idler deflects forward) to prompt the belt to deviate to the right and center.