Pulley assembly is an important part of the belt conveyor. As per different performance, it can be classified into drive pulley and bend pulley. The function of the driving pulley is to transfer the torque generated by the driving device to the conveyor belt. The bend pulley includes reversing pulley for belt direction change at the end of the conveyor, guide pulley and snub pulley for increasing the covering angle, guide pulley for tightening the device.

Features:

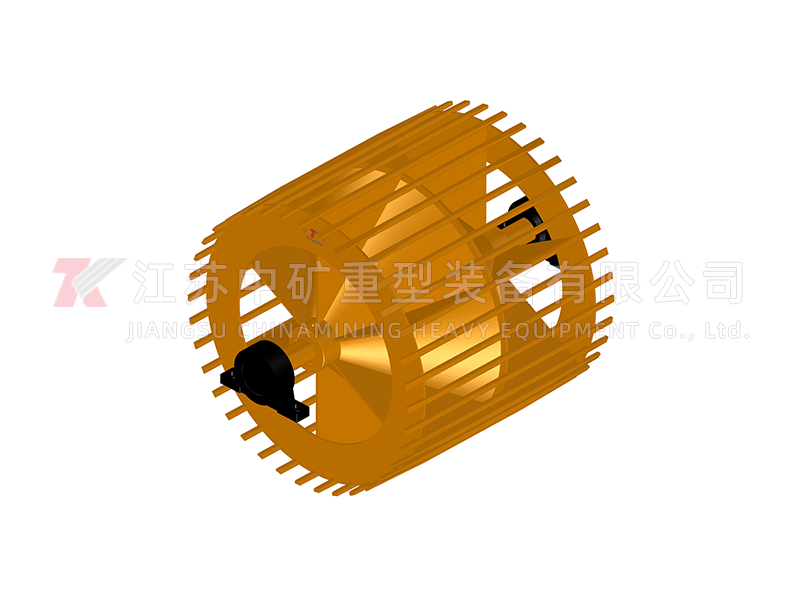

1. The slag pulley is used as the tail pulley or snub pulley, which can clean the materials properly on the conveyor belt.

2. The bearing housing has a unique sealing design to ensure proper operation of the pulley.

3. The slag pulley can improve the service life of adhesive belt.The slag pulley is applied to belt conveyors. The principle of the slag pulley is to have a long hole parallel to the axial direction on the surface of the pulley. When material enters the return belt, it can enter this long hole and then enter the pulley. Inside the pulley, there is a double cone pulley with two pointed ends and a thick center, with holes at both ends. After passing through the axial long holes on the surface of the pulley, the material enters the pulley and is discharged into the material yard through the cone and end holes, avoiding the material from being constantly pressed and worn on the belt at the changing direction of the drum and improving the service life of the belt. This product is particularly suitable for the turning point pulleys of bucket wheel reclaimers in steel raw material plants, dock yards, power plants and coal yards. When there is a large amount of material on the return belt, it can be discharged from the return belt.