The self-locking protection device for inverted and broken belt catcher is equipped on the belt conveyor with an inclination angle.

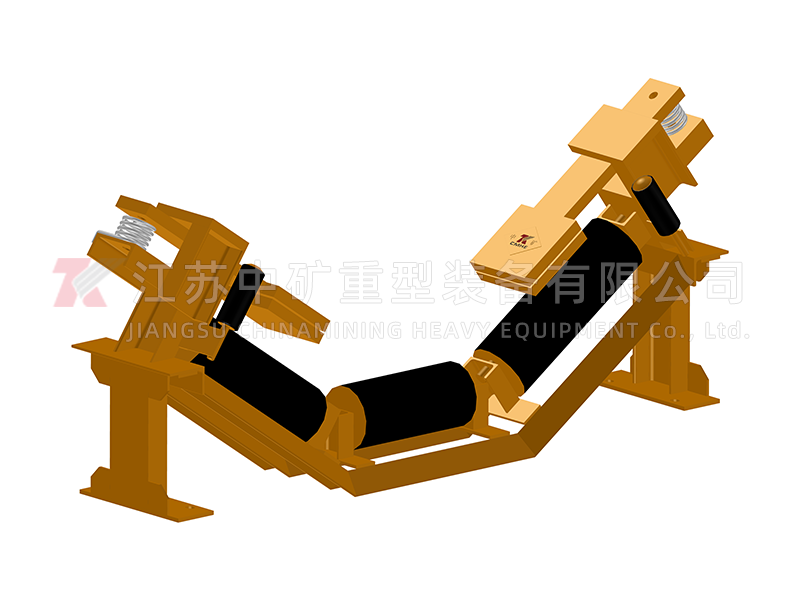

1. The self-locking protection device for inverted and broken belt catcher includes three parts: inverted and broken belt detection device, inverted and broken belt self-locking device, and control box of inverted and broken belt.

2. The self-locking protection device for inverted and broken belt catcher is symmetrically installed on both sides of the belt, and can protect 50% of the total length of the belt according to the load tension of the belt conveyor. The tensile strength of the belt catcher device is greater than 5 tons, and the belt cannot be damaged during operation. The belt can be locked within 0.5 seconds.

3. Each belt self-locking device brake is equipped with one set of control box.

4. If there is a belt breakage or a failure of the backstop, the belt will slide down and drive the eccentric roller to rotate. At the same time, the driving device will act, and the brake beam will rotate to a position parallel to the eccentric roller under the action of the spring and its own gravity, gradually reducing the gap between the brake shoe and the eccentric rollers on both sides, and quickly capturing the sliding section of belt firmly.

5. When the belt conveyor is running normally or stopped, the reverse detection device does not issue an alarm signal. When the belt breaks, the belt slides down and drives the detection device's contact wheel to reverse, issuing an alarm signal. The principle of the belt broken detection device is to send an alarm signal to detect belt breakage accidents after the limitswitch and proximity switch on the tensioning device are activated. The proximity switch on the self-locking device is used to detect whether the inverted and broken self-locking device is activated. Display the working status of the inverted and broken belt protection device on the electrical control box and output an alarm.

6. The self-locking protection device for inverted and broken belt catcher mainly includes the following parts: belt reversal detection device, counterweight (tensioning device) limit detection device, electric device and the self-locking protection device of inverted and broken belt catcher, electric control box, etc. The protection device of inverted and broken belt catcher has the function of detecting the reverse and breakage of the belt conveyor, as well as the alarm and display function of the reverse and breakage action. When the backstop fails or the belt breaks, it is driven by the electric device to quickly lock the heavy and empty sections of the belt that suddenly slide down due to the breakage (or loss of control) of the belt.

7. The detection of reverse and breakage adopts a combination of hydraulic tension signal of the belt and belt contact triggering, with sensitive and reliable triggering action.

8. The self-locking protection device for inverted and broken belt catcher is driven by an electric device, with a braking force greater than 5 tons and an action time of less than 0.5 seconds.

9. The self-locking protection device for inverted and broken belt catcher adopts partial section braking, which can open the swinging brake block mechanism. The brake beam rotates to a parallel position with the conveyor during normal operation of the belt conveyor, avoiding the influence of the brake block on the conveyed material.

10. The self-locking protection device for inverted and broken belt catcher meets the requirement of continuous debugging to ensure the reliability of the device's operation.

11. The self-locking protection device for inverted and broken belt catcher not only has the function of belt breakage protection, but also can prevent deviation.