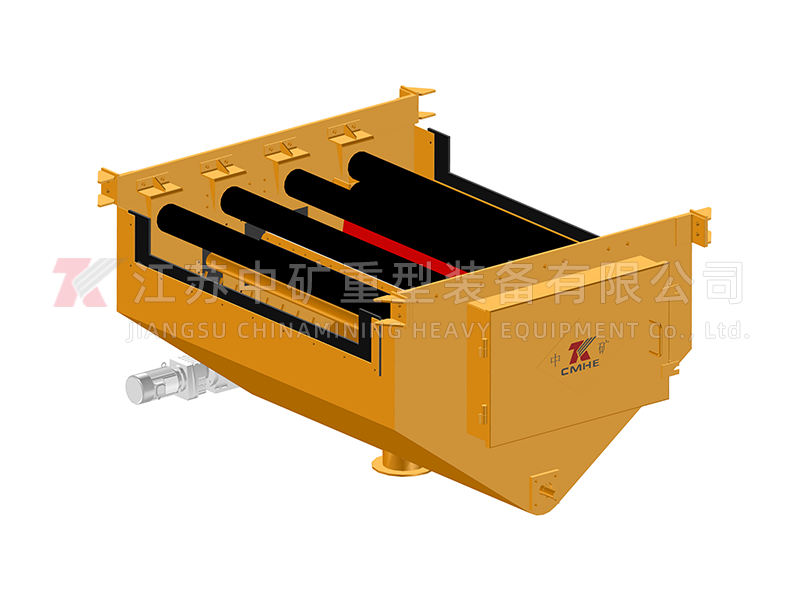

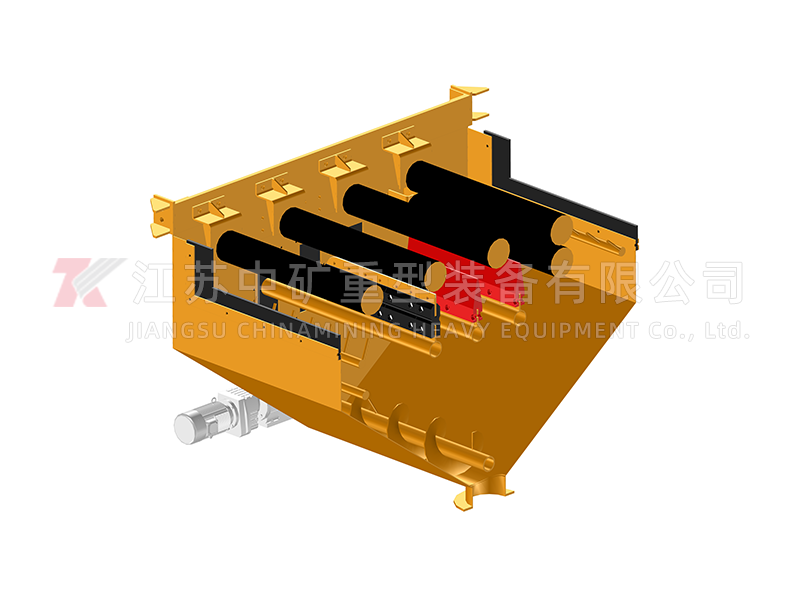

To thoroughly remove the adhesive material of the belt and prevent contamination of the return ground of the belt conveyor, a belt cleaning device is installed behind the driving snub pulley at the head of the conveyor. The cleaning device has four cleaning methods: water spraying, scraping, wiping, and air drying.

1. The operation of the belt cleaning device should not be affected by moisture and impurities in the material, and there should be no nozzle blockage. And it has good cleaning ability, with a cleaning rate of no less than 95% for removing residual materials from the return belt.

2. The belt cleaning device includes pressure idlers, water spray pipes or atomizing nozzles that cover the width of the belt load conveying, tungsten carbide alloy blade heads, polyurethane blade materials for drying, air knife blowing, drying and other belt cleaning and cleaning equipment.

(1)Spray system: The belt cleaning system is equipped with a set of spray belt cleaning system, which is directly installed at the rear of the head transfer groove. It can remove all residual debris on the belt by highpressure spraying and soften the adhesive.

(2) Scraping device: using tungsten carbide alloy blade and imported flexible polyurethane blade material to remove all materials, mud, and moisture adhered to the belt.

(3) Drying device: High pressure air knife is used to fully dry the residual moisture on the surface of the belt to prevent wet belt from sticking materials circularly.

(4) Sewage discharge system: The sewage in the cleaning device is promptly discharged through a screw conveyor using a spraying method to prevent blockage of the sewage tank.

3. The noise level of the belt cleaning device during operation is less than 60 decibels, which complies with relevant national standards.

4. The main components of the belt cleaning device, such as the nozzle and the belt cleaner blade, are easy to replace.

5. Applied to the conveyance of all kinds of materials and widely used in industries such as building materials, metallurgy, chemical industry, petrochemical industry, coal industry, mining, papermaking, electricity, ports and terminals.