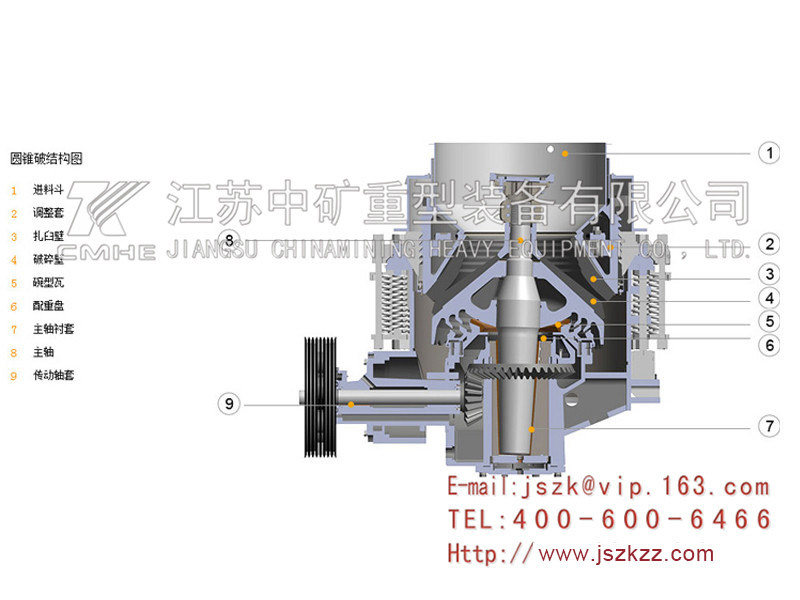

Cone crusher

Overview and Application of Cone Crusher

Cone crusher is widely used in mining industry, metallurgy industry, construction industry, road construction industry, chemical industry and silicate industry. It is suitable for crushing hard and medium hard ores and rocks, such as iron ore, limestone, copper ore, quartz, granite and sandstone. The cone crusher has the characteristics of large crushing force, high efficiency, high processing capacity, low operating cost, convenient adjustment and economical use. Due to reasonable material selection and structural design of the parts, the service life is long and the particle size of the crushed products is uniform, reducing the cyclic load. In medium and large-sized crushers, hydraulic cleaning system is adopted, reducing downtime. Moreover, there are multiple chamber types for each specification of crusher, and users can choose different chamber types according to different requirements so as to meet their needs. This machine is sealed with lubricating grease to avoid the problems of easy blockage in the water supply and drainage system as well as the defects of easy mixing of water and oil. The spring safety system is an overload protection device that can prevent foreign objects and iron blocks from harming the crusher when passing through the crushing chamber.

Working principle of cone crusher

When the cone crusher is working, the electric motor rotates the belt pulley or coupling and then the rotational pendulum motion of the transmission shaft and the cone part of the cone crusher is made around a fixed point under the force of the eccentric sleeve. As a result, the crushing wall of the crushing cone approaches and leaves the surface of the rolling mortar wall fixed on the adjustment sleeve by turns, causing the ore to be continuously impacted, compressed and bent in the crushing chamber, achieving the crushing of the ore. The electric motor drives the eccentric sleeve to rotate through the umbrella gear, causing the crushing cone to rotate and swing, which approaches and leaves the fixed cone by turns to complete crushing and discharging. The connection between the support sleeve and the frame is tightly pressed by spring. When an unbreakable object such as a metal block falls into the crusher, the spring undergoes compression and deformation, expelling foreign objects, achieving safety and preventing machine damage. When an unbreakable foreign object passes through the crushing chamber or the machine is overloaded for some reason, the spring safety system of the cone crusher realizes safety, and the discharge port of the cone crusher increases. Foreign objects are discharged from the crushing chamber of the cone crusher. If foreign objects get stuck in the ore discharge, a cleaning system can be used to increase the ore discharge and allow the foreign objects to be discharged from the crushing chamber of the cone crusher.Under the action of the spring, the cone crusher automatically resets the ore discharge port, and the cone crusher machine returns to normal operation. The surface of the crushing chamber is covered with high manganese steel lining plate. The size of the ore discharge port is adjusted by hydraulic or manual means.

Technical Parameter

Model | (mm) Diameter of crushing cone | (mm) Max. feed particle size | mm) Adjustment range of discharge port | (t/h) Processing capacity | (kW) Motor power | (r/min) Number of spindle swings | (mm) External dimensions |

PYB900 | 900 | 115 | 12-50 | 50-90 | 55 | 333 | 2692×1640×2350 |

PYZ900 | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 2692×1640×2350 |

PYD900 | 900 | 50 | 3-30 | 15-50 | 55 | 333 | 2692×1640×2350 |

PYB200 | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 2790×1878×2844 |

PYZ200 | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 2790×1878×2844 |

PYD200 | 1200 | 50 | 3-25 | 18-105 | 110 | 300 | 2790×1878×2844 |

PYB750 | 1750 | 215 | 25-60 | 280-480 | 160 | 245 | 3910×2894×3809 |

PYZ750 | 1750 | 185 | 10-30 | 115-320 | 160 | 245 | 3910×2894×3809 |

PYD750 | 1750 | 85 | 5-15 | 75-230 | 160 | 245 | 3910×2894×3809 |

PYB2200 | 2200 | 300 | 30-60 | 590-1000 | 280 | 220 | 6440×2900×5057 |

PYD2200 | 2200 | 100 | 5-15 | 120-340 | 280 | 220 | 6440×2900×5057 |