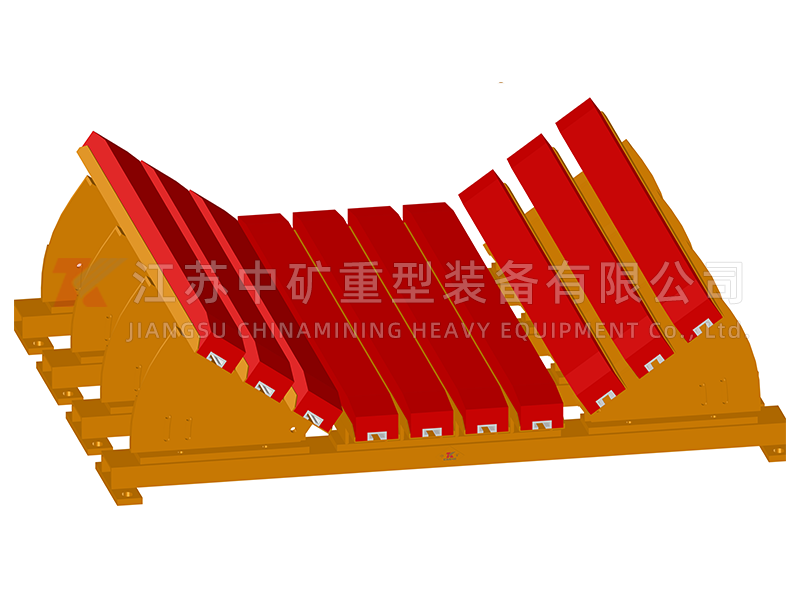

An impact bed is configured at the falling point under the guiding chute of belt conveyors to reduce the impact of the feeding point and prevent the belt from tearing.

1. The impact bar of the impact bed is vulcanized and made of ultra-high molecular weight polyethylene plate, natural rubber and aluminum alloy with great stability and reliability.

2. The surface material of the impact bar adopts UHMW-PE material, with smooth surface and high wear resistance, which can reduce the friction resistance and prolong the service life.

3. The single piece is a seamless integrated structure. The upper impact plate should have low wear and friction, the middle impact bar rubber should have strong buffering and shock absorption properties, and the connection between the lower bed and rubber should be convenient and reliable, making it easy to quickly replace the impact bar and facilitate installation and maintenance.

4. The angle design on both sides of the impact bed should be suitable for the requirements of different conveyor capacities and bandwidths, should be stepless adjustable and can be placed flat and used for special working conditions at the receiving point.

| Model | Belt width | L | Number of seats | |

| ZK-HCC | 065 | 650 | 650 | 3 |

| 080 | 800 | 800 | 4 | |

| 100 | 1000 | 1000 | 4 | |

| 120 | 1200 | 1200 | 4 | |

| 140 | 1400 | 1400 | 4 | |

| 160 | 1600 | 1600 | 4 | |

| 180 | 1800 | 1800 | 4 | |

| 200 | 2000 | 2000 | 4 | |

| Note: Can be customized according to customers’ specific requirements | ||||