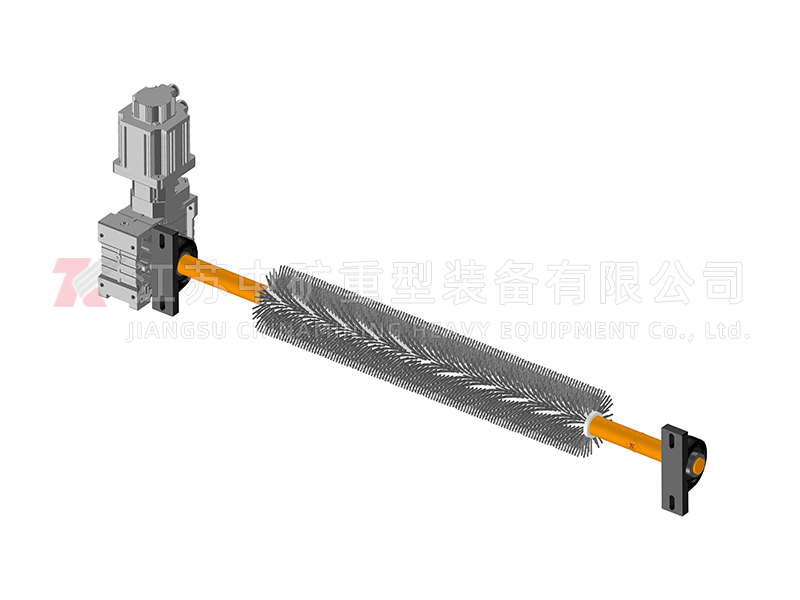

The motorized brush belt cleaner is composed of motor, reducer, rolling brush, coupling, bearing seat and adjusting frame. The rolling brush is driven by a motor, and the brush tip is in slight contact with the belt surface. The rotating direction of the brush is opposite to the running direction of the return conveyor belt, so as to brush down the adhesive material stuck on the belt surface, especially on the pattern. The reasonable and compact structure makes the cleaner safe and reliable, which can effectively clean the surface of the belt without damaging the belt, effectively extends the service life of the belt conveyor and improves work efficiency.

1. The roller brush is made of wear-resistant nylon wire arranged in a spiral shape along the shaft, free from material and scale. Especially suitable for cleaning old belts with uneven surfaces and belts with mechanical joints;

2. Continuous contact of the cleaning point when the cleaner works, makes the cleaning force strong and the cleaning effect good;

3. Safe and reliable, low failure rate, long service life, low maintenance cost;

4. Applied to the conveyance of all kinds of materials and widely used in industries such as building materials, metallurgy, chemical industry, petrochemical industry, coal industry, mining, papermaking, electricity, ports and terminals.

| Model | Belt width | Brush length | Total length | Motor power(Kw) | |

| ZK-EPM | 065 | 650 | 650 | 1300 | 1.5 |

| 080 | 800 | 800 | 1450 | 1.5 | |

| 100 | 1000 | 1000 | 1650 | 1.5 | |

| 120 | 1200 | 1200 | 1850 | 1.5 | |

| 140 | 1400 | 1400 | 2050 | 2.2 | |

| 160 | 1600 | 1600 | 2250 | 2.2 | |

| 180 | 1800 | 1800 | 2450 | 2.2 | |

| 200 | 2000 | 2000 | 2650 | 2.2 | |

| 220 | 2200 | 2200 | 2850 | 2.2 | |

| Note: Can be customized according to customers’ specific requirements. | |||||