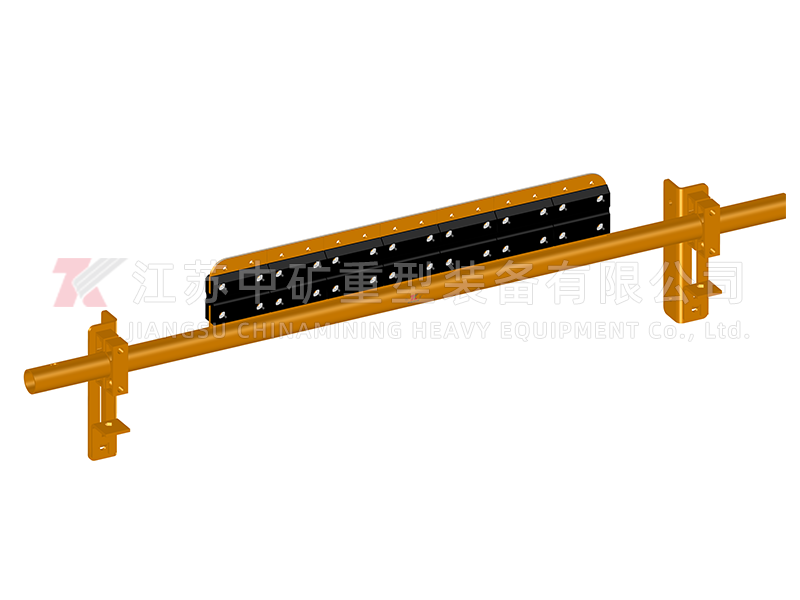

Suitable for cleaning residual materials on the surface of the conveyor belt at the discharge drum of the belt conveyor, abbreviated as head/secondary/first stage/H-type.

1. The blade adopts a split structure with a single blade length of 200mm and is assembled from natural rubber blocks and tungsten carbide composite nano materials, suitable for bidirectional operation of belt conveyors, with more uniform cleaning force and a long service life of the cleaner.

2. Tensioner integrated casting component, sturdy and durable. The unique fastening bolts can maintain tightness even in frequent vibration working environments, improving the reliability of the product.

3. Used for the second cleaning of attachments on the lower surface of high-speed return belts of belt conveyors for transporting materials with high water content, such as coal slurry.

4. Installed at the return section below the unloading pulley, it solves the problems of environmental pollution caused by residual materials spilling on the conveyor return section and deviation of the return belt caused by residual materials sticking to the rollers.

5. Applied to the conveyance of all kinds of materials and widely used in industries such as building materials, metallurgy, chemical industry, petrochemical industry, coal industry, mining, papermaking, electricity, ports and terminals.

| Model | belt width | Steel tube length | Blade length | |

| ZK-PHM | 065 | 650 | 1600 | 600 |

| 080 | 800 | 1800 | 700 | |

| 100 | 1000 | 2000 | 900 | |

| 120 | 1200 | 2200 | 1100 | |

| 140 | 1400 | 2400 | 1300 | |

| 160 | 1600 | 2700 | 1500 | |

| 180 | 1800 | 3000 | 1700 | |

| 200 | 2000 | 3200 | 1900 | |

| 220 | 2200 | 3500 | 2100 | |

| 240 | 2400 | 3800 | 2300 | |

| Note: Can be customized according to customers’ specific requirements. | ||||