Stone crushing production line

Stone production line (gravel production line) can be used for hard limestone, granite, basalt, river pebbles, iron ore and other materials of aggregate and artificial sand operations, suitable for hydropower, building materials, highways, urban construction and other industries. Production and processing of highway surface materials, high-grade highway pavement gravel, high-speed railway passenger line sand and gravel aggregate, hydropower station sand and gravel, port terminals and airport runway gravel and other special construction fields are particularly suitable.

The stone production line is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electric control and other equipment. The design output is generally 50-500 tons/hour. In order to meet the different processing needs of customers, it can be equipped with cone crusher, dust removal equipment, etc.

The equipment configuration of the stone production line is mainly determined by the customer's specifications, output and use of the stone. We provide comprehensive services before, during and after sale, and configure the process according to the customer's production site, and strive to configure a reasonable and economical stone production line for the customer. The large stone is uniformly sent to the jaw crusher by the vibrating feeder for coarse crushing, and the roughly crushed stone is sent to the impact crusher by the belt conveyor for further crushing; the finely crushed stone is sent to the vibrating screen by the belt conveyor for screening, and several stones of different specifications are screened out. The stones that meet the particle size requirements are sent to the finished material pile by the finished product belt conveyor; the stones that do not meet the particle size requirements are returned by the belt conveyor to the impact crusher for re-crushing, form a closed loop multiple times. The particle size of the finished product can be combined and graded according to the needs of users. In order to protect the environment, auxiliary dust removal equipment can be equipped.

High automation efficiency

The stone crushing production line has high automation process, large crushing ratio, high production efficiency and large processing capacity. After crushing the product is a cube, needle, flake content is low, no internal cracks, compressive strength to engage.

Loss of small income large operation cost is low.

Equipment maintenance is simple, wearing parts using the current domestic wear-resistant materials, small loss of long service life, can bring considerable economic benefits for customers.

From product design, raw material procurement to production and processing, we pay attention to every link and detail. A large number of new technologies, new processes and new materials are used to ensure the quality of products.

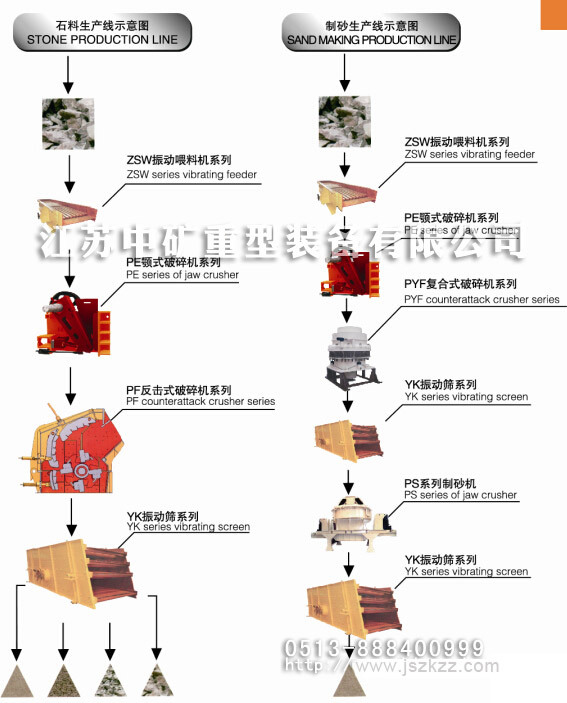

stone production line schematic diagram:

ZSW vibrating feeder series -->PE palate crusher series --> PF counterattack crusher series -->YK vibrating screen series

sand production line schematic diagram:

ZSW vibrating feeder series -->PE palate crusher series --> PYF composite crusher series -->YK vibrating screen series -- >PS series sand making machine -->YK vibrating screen series