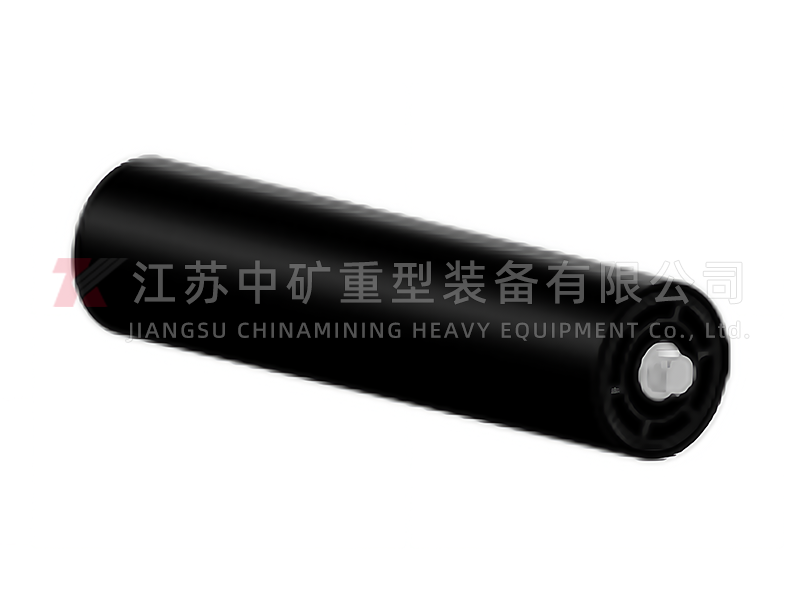

High molecular idler roller is a new generation roller product developed by ChinaMining Company,which can extend the service life of equipment, save energy, and effectively improve the working environment. It has been widely used in transportation systems in industries such as building materials,metallurgy, chemical engineering, petrochemicals, coal, mining, papermaking, electricity, ports and terminals. it is an ideal replacement product for steel rollers in belt transportation machinery.

1.Long service life .longer than traditional steel rollers.

2.Protect the surface of the belt polymer roller tube from being smooth, non-magnetic, and not adsorbingiron powder, dust, and various viscous substances, The friction coefficient with the belt is extremely low, and it has self-lubricating properties, which can effectively protect the belt and extend its service life,

3.Lightweight - easy to construct and install, while also having good energy-saving effects;

4.Maze design - a special labyrinth seal design that completely isolates the bearing from contact with the outside world, effectively protecting the bearing.

5.Low noise - effectively improves the working environment;

6.Special working conditions - acid, alkali, salt and other chemically corrosive working conditions.