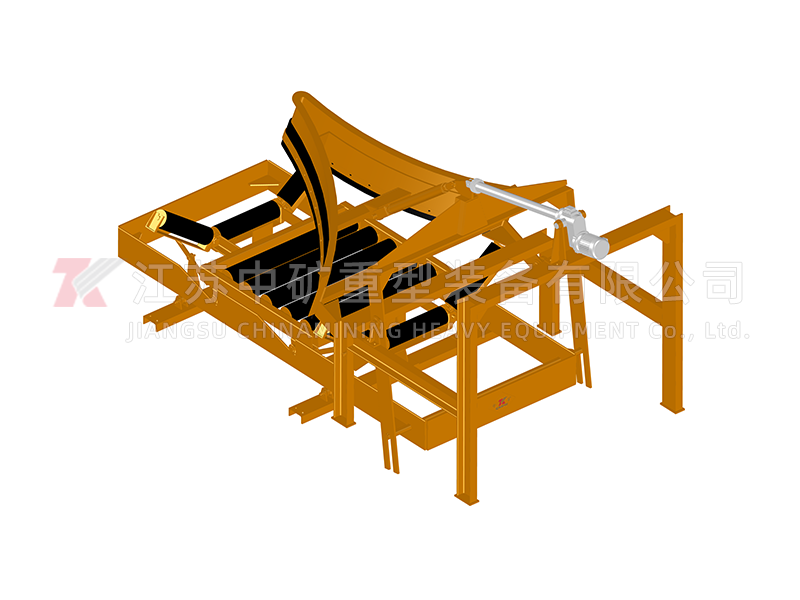

The plow unloader is powered by electric hydraulic push rod. During operation, the push rod extends to act on the driving rod, driving the frame forward, completing the plow blade's descent, and supporting the flat idler group to make the working surface of the belt flat. The lower edge of the plow blade is tightly attached to the belt surface, and the material on the running belt is unloaded into the funnel (hopper) or to the required location. When unloading is completed, the push rod is activated to retract and act on the driving rod, driving the frame to retreat, the plow blade to lift, and the idler group of variable groove angle to return to the groove shape from the flat shape, restoring the groove shape of working surface of the belt and allowing the material to pass smoothly. Due to the use of hydraulic transmission, the electric hydraulic push rod has automatic overload protection performance. When the operation is obstructed, the pressure in the oil circuit increases o the set limit and the overflow device quickly and accurately overflows, implementing overload protection.

1. The plow head is divided into a front plow head made of high chromium alloy and a rear plow head made of wear-resistant rubber plate, making the unloading cleaner.

2. The locking device added to the plow head is a mechanical grab and pull type, which can adjust the height of the plow blade to be closest to the belt in the best possible way. During operation, the plow blade will not lift or shake due to the impact force of coal, avoiding tearing, wear and coal leakage of the belt.

3. As the driving part is the latest product in China, the mechanical electro-hydraulic push rod can be used both manually and electrically, overcoming the shortcomings of poor overload capacity, motor burnout, jamming and top bending screw of electric push rods as well as new drawbacks such as internal and external leakage, non self locking, sliding and crawling of ordinary electro-hydraulic push rods. The manual and electric dual-purpose mechanical electro-hydraulic push rod has the advantages of absolute self-locking, no internal or external leakage, great overload capacity and smooth operation.

4. The installation methods are divided into three types: A, B, and C. The electro-hydraulic push rod can be placed on the upper part of the coal separator and installed vertically, and there are three options for installation on both sides of the belt, which is very convenient for customers.

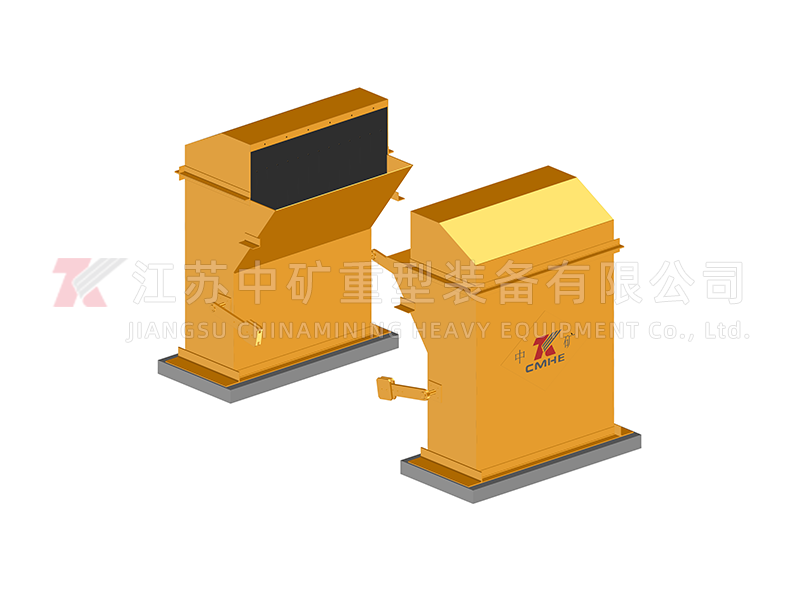

5. The flap of the air lock can be made of high manganese chromium wear-resistant material, which extends the service life by up to 20 years and reduces maintenance costs.

6. The use of the air locking part:

(1) To evenly distribute the material, prevent deviation, sticking, and scattering along the way.

(2) To reduce induced blowing to reduce its deceleration to below 10% of its original level.

7. Applied to the conveyance of all kinds of materials and widely used in industries such as building materials, metallurgy, chemical industry, petrochemical industry, coal industry, mining, papermaking, electricity, ports and terminals.