1. Working principle

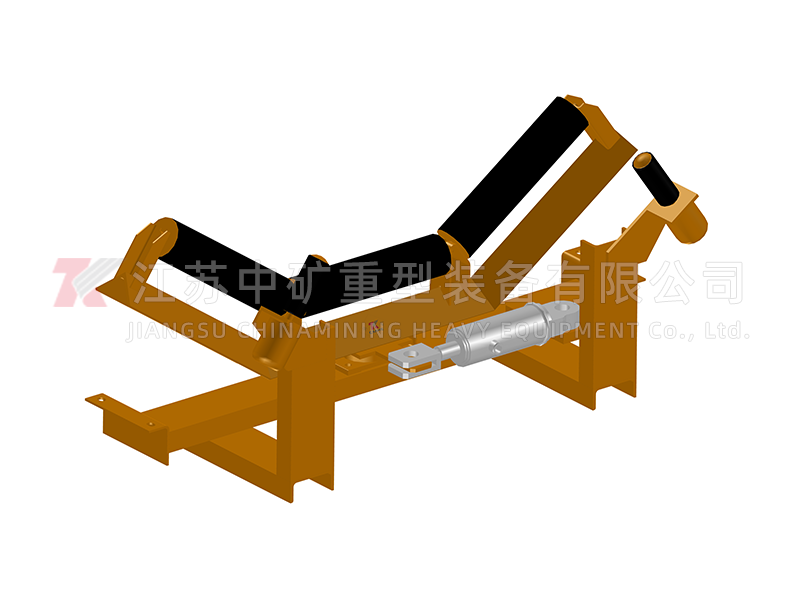

The device is composed of a power output device consisting of a testing wheel and an oil pump, a logic valve and an oil cylinder, and then connected with the self-aligning idlers bracket. It is normal operation when the belt moves in the middle and does not contact to the two testing wheels. If the belt runs to the left, the left power output device get started, the actuator will adjust the rectifying roller position according to the judgment of logical valve to generate a reverse thrust, and push the belt to the middle. Contrarily, if the belt runs to the right, the right power output device get started, the actuator will judge the rectifying roller position according to the judgment of the logical valve to generate a reverse thrust, push the belt to the middle. The idlers make the belt always running in the setting width range, which avoids belt tearing, machine halt and material sprinkling due to the belt deviation, ensuring the normal running of the conveyor.

2. Features and advantages:

(1) Suitable for one-way or two-way running belt, with better adaptability;

(2) The whole frame (rotating beam and supporting beam) is made of high-strength square steel, with high strength, wide application range, easy installation and stable operation;

(3) Suitable for the working places requiring sensitive deviation correction or having difficult daily maintenance and severe working environment.