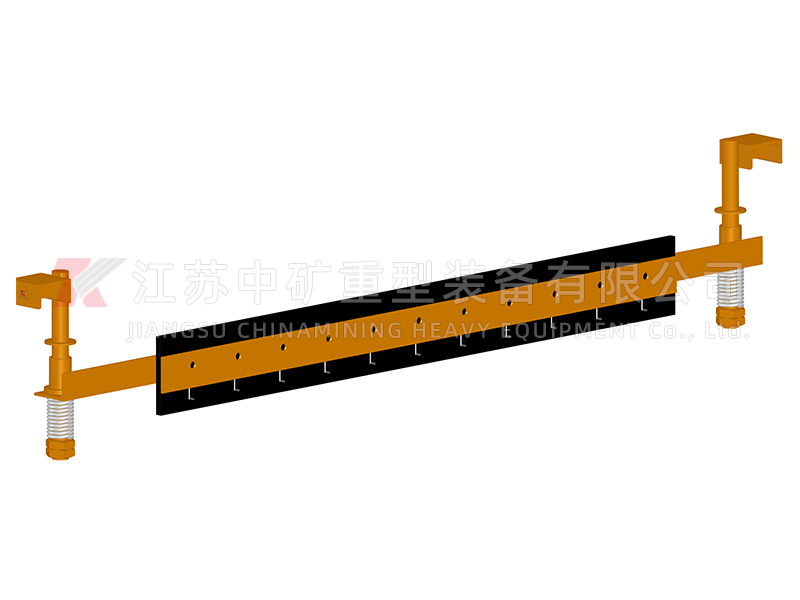

Suitable for cleaning residual materials on the surface of the conveyor belt at the discharge drum of the belt conveyor, abbreviated as head/primary/first stage/H-type.

1. The blade is made of specially modified polymer polyurethane, which has the characteristics of flame retardant and anti-static properties, high wear resistance, high elasticity, acid and alkali resistance and low friction coefficient;

2. Polyurethane and aluminum alloy sliding groove are vulcanized together;

3. Two sets of constant pressure spring adjustment seats at each end ensure appropriate contact pressure between the scraper and the belt. When subjected to external impact, the pressure spring can buffer the impact force in a timely manner to prevent the scraper from damaging the belt:

4. Curved blade, matching the shape of the drum to ensure effective use of the blade; One-piece blade, the contact surface, inclination angle and pressure between the blade and the belt are constant, and the scraping effect is stable.

5. The length can be customized according to the width of the belt or the requirements of the working conditions, and the applicable bandwidth is B500-2400mm.

6. Applied to the conveyance of all kinds of materials and widely used in industries such as building materials, metallurgy, chemical industry, petrochemical industry, coal industry, mining, papermaking, electricity, ports and terminals.

| Model | Belt width | Steel tube length | Blade length | |

| ZK-HJ | 065 | 650 | 1600 | 600 |

| 080 | 800 | 1800 | 700 | |

| 100 | 1000 | 2000 | 900 | |

| 120 | 1200 | 2200 | 1100 | |

| 140 | 1400 | 2400 | 1300 | |

| 160 | 1600 | 2700 | 1500 | |

| 180 | 1800 | 3000 | 1700 | |

| 200 | 2000 | 3200 | 1900 | |

| 220 | 2200 | 2500 | 2100 | |

| 240 | 2400 | 2800 | 2300 | |

| Note: Can be customized according to customers’ specific requirements. | ||||