Air cannon

Ⅰ. Purpose

Jiangsu ChinaMining Air Cannon is mainly used for cleaning various materials in places such as silos, hoppers, pipelines, shafts and slopes that are prone to sticking and arching in industries such as power, cement, and building materials. It can also be widely used in industries such as metallurgy, chemical industry and coal. It has the characteristics of low energy consumption, low investment and easy maintenance. It is ideal spark-free cleaning equipment.

Ⅱ. Product Features

Installation and maintenance are very convenient: the quick release valve and solenoid valve are integrated, and the vulnerable parts such as the valve plate diaphragm and solenoid valve can be easily replaced.

The control part is simple and flexible: it can easily achieve local or central control. The solenoid valve only requires an electrical pulse of 220V, 0.5s to release.

The requirements for compressed air quality are greatly reduced: due to the use of aluminum alloy in the valve body, there is a problem of corrosion. The main valve plate diaphragm is made of imported rubber, which greatly reduces corrosion and is waterproof and oil proof.

Long service life: The quick release valve for vulnerable parts adopts ASCO original valves, with a service life of up to 1 million times.

Reliable and strong impact force: The KST air cannon body of Nantong ChinaMining is strictly designed and manufactured according to the manufacturing standards of national pressure vessels. Due to the use of imported solenoid valves, the valve body has fast release speed and strong impact force.

Low noise: After on-site testing, the noise value of KST air cannon is lower than that of industrial enterprises and lower than the noise standard of industrial enterprises.

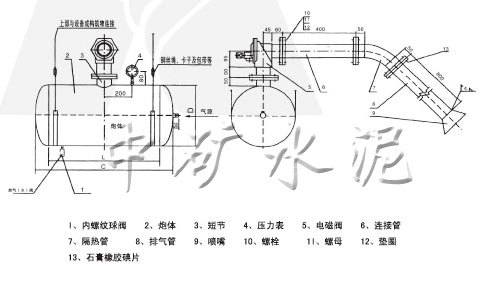

Ⅲ. Layout diagram of air cannon

Ⅳ. Air Cannon Performance Table

Control principle and function

After the operator starts the operation, the PLC starts the first electromagnetic valve according to the pre-programmed program, and the corresponding first air cannon starts; After a certain delay by the PLC, the second solenoid valve is activated, and the corresponding second air cannon is activated until it reaches the five solenoid valves. After the corresponding fifth air cannon is activated, the PLC delays for a period of time before starting the next cycle of control. All delay times can be adjusted online at any time. The control device also has a manual control function, where the operator manually activates each solenoid valve and the corresponding air cannon is activated.

Design principles

Reliability: Ensure that the system can operate continuously and reliably for a long time

Economy: Principle of complete functionality and high/low cost performance ratio

Friendly: System installation, software configuration, simple operation, and easy maintenance.

Equipment Selection

The controller generally adopts Japanese Omron's PLD (other manufacturers can be selected according to user requirements) with strong anti-interference ability, interchangeable models and high reliability. The 24V switching power supply has good heat dissipation, fast short-circuit (overload) protection, stable output voltage, small size and convenient installation. Spark-free switch has strong adaptability to the surrounding environment.

Ⅴ. Ordering Instructions

The control box is an accessory and can be ordered separately if needed by the user;

To increase the safety of the air cannon, each air cannon can be equipped with a gun body protection valve.