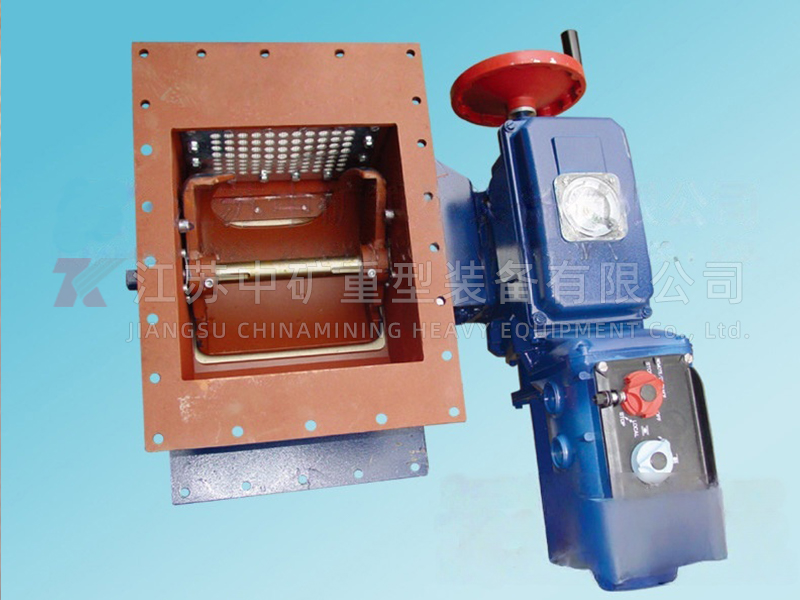

FLD\FKQ-N flow valve, switch valve

1. Overview

The flow control valve is used to control the amount of material discharged from the bottom of the reservoir and is usually used together with the rotary valve. The material passes through a small chute to fluidize the material, and then enters the flow valve, which can avoid the formation of a material column in the flow control part. The opening of the flow control valve is adjusted by an electric actuator, and the opening of the valve can be controlled remotely to meet the requirements of system statistics. The rotary valve is mainly used as a switch in the material flow control system, and is usually used in series with the electric flow control valve. Widely used in building materials, metallurgy, chemical industry, food, glass and other industries.

2. structure characteristics

The design of the flow control valve and rotary valve is scientific and reasonable, the mechanism is compact, the valve core is provided with a U-shaped notch, the opening of the adjustment groove can be controlled for flow, the indicator disc can indicate the opening of the valve core, the coupling between the valve core and the electric actuator is additionally provided with a safety pin to ensure that the valve core and the actuator are not damaged, and the radial gap between the gasket and the valve core can be adjusted to ensure the flexibility of the operation of the valve core. Flow control valves are equipped with DKJ actuators. The rotary valve is equipped with a 10-5A pneumatic push rod.

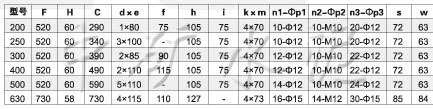

3. performance parameters

4. working principle

The flow control valve is mainly composed of organic seat, valve body, sealing valve, bushing valve core, bearing breathable layer, inflatable groove and transmission device. The fan gives low-pressure and small-capacity air, which is inflated by the inflation groove through the channel opening. The gas penetrates through the breathable layer and is evenly blown upward to encourage the material to move upward. When the material falls under its own weight, the equipment installation slope produces displacement, which repeatedly causes the material to move forward. Actuator Fu dynamic coupling spool action to regulate material flow. The rotary valve is only used as a switch, and the air source of the pneumatic push rod is controlled by the solenoid valve to command the push rod action to complete the switching action.

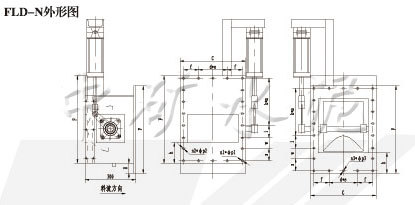

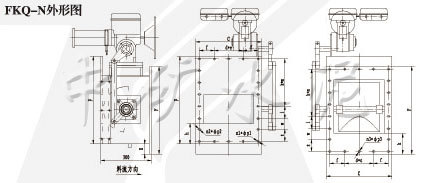

5. outline connection dimension

6. instructions for use

Before installation, please check whether there is debris attached to the inner cavity, otherwise it will block the U-shaped spool and damage the valve. Check whether the boiling plate is damp. If the boiling plate is damp, please replace it before installation, otherwise it will affect the use effect. Check whether each transmission part is flexible and reliable. During installation, the transmission part is not allowed to be hoisted and is not allowed to be damaged. A sealing gasket shall be added in the middle of the two flange connections, and then the connecting bolts shall be tightened evenly.