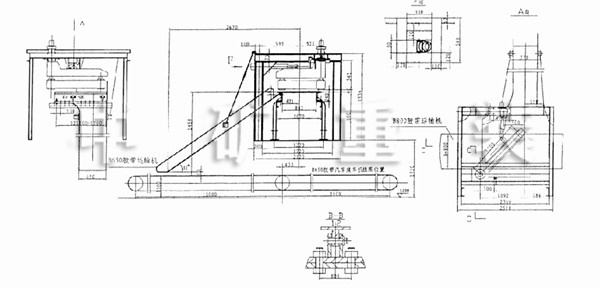

Electric turning slide

Technical Specifications

Conveying Material: Bagged Cement (50kg/bag)

Cycloidal Pinwheel Reducer

(1) Model: BL15-9-1.1

(2) Speed Ratio: 9

(3) Motor Specifications:

- Model: Y90S-4

- Power: 0.55 kW

- Speed: 1410 r/min

Electric Linear Actuator

(1) Model: DT300-60

(2) Thrust: 300 kg

(3) Speed: 84 mm/s (Note: Verify unit if required)

(4) Motor Specifications:

- Model: A06332

- Power: 0.55 kW

- Speed: 2800 r/min

- Voltage: 380 V

- Current: 1.38 A

Limit Switch

(1) Model: JLXK1-111

(2) Voltage: 380 V

(3) Current: 5 A

Technical requirement:

The arrow in the A-direction view indicates that the cement package is transported from electric turning chute of B800 belt conveyor to B650 belt conveyor.

The cement package that is fed into the electric bending roller by B800 belt conveyor should be placed in a clockwise manner, and there should be no horizontal wrapping.

The travel switch (serial number 22) is installed on site.

Drill on site for the production and installation of the connecting frame, and remove the corresponding rollers from B800 belt conveyor.

Installation and operation instructions for electric turning chutes

Electric turning slider consists of steel frame, rotating belt turning mechanism, electric push rod,sliding slider and control system. Electric turning chutes are mainly used for turning and conveying bag packaging materials from one conveyor belt to another conveyor belt that is perpendicular to it in the lower layer. It is suitable for automatic conveyor lines of cement, grain, chemical and other industries, which can automatically transfer bagged materials to another line.